Noise-cancelling headphones have become a popular accessory for frequent flyers. By analyzing the background frequencies produced by an airplane in flight and generating an "anti-noise" sound wave that is perfectly out of phase, such headphones eliminate disturbing background sounds. Although the headphones can't do anything about the cramped seating, they can make watching a film or listening to music in flight nearly as enjoyable as at home.

To minimize the disturbing noise caused by loud machines like cars, ships, and airplanes, acoustic engineers use many strategies. One technology, called a Helmholtz cavity, is based on a similar concept to that used in noise-cancelling headphones. Here, engineers build a resonating box that opens to a slit on one side. As air passes over the slit, the box vibrates like a church organ pipe, producing a tone. By adjusting the size and shape of the cavity and its slit, acoustic engineers can tune it to produce a specific tone that — like the headphones — cancels a dominant, irritating sound produced by machinery.

Historically, the process of tuning a Helmholtz cavity was a brute force undertaking involving costly and time-consuming trial and error. Engineers had no other choice but to physically build and test many different geometries experimentally to find an optimal shape for a specific application, especially in an environment of turbulent flow.

Today, however, high-performance computing offers the potential to undertake such tests virtually, making the design process faster and easier.

Read more at Gauss Centre for Supercomputing

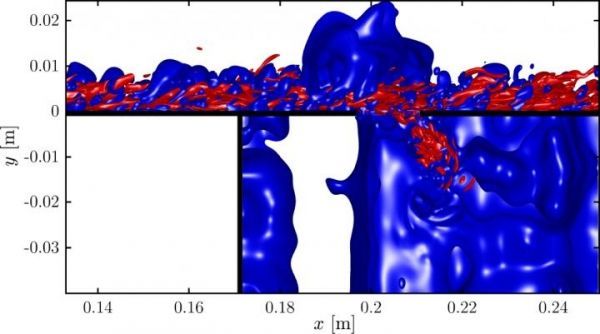

Image: At the top, vorticity isosurfaces (± 3,000 Hz, colored blue and red) of the turbulent flat-plate flow are visible. Below the flat-plate flow, the rectangular box of the resonator is mounted. (Credit: Courtesy of Lewin Stein, TU Berlin.)