Hydrogen is a critical component in the manufacture of thousands of common products from plastic to fertilizers, but producing pure hydrogen is expensive and energy intensive. Now, a research team at Princeton University has harnessed sunlight to isolate hydrogen from industrial wastewater.

In a paper published February 19 in the journal Energy & Environmental Science, the researchers reported that their process doubled the currently accepted rate for scalable technologies that produce hydrogen by splitting water.

The technique uses a specially-designed chamber with a “swiss-cheese” black silicon interface to split water and isolate hydrogen gas. The process is aided by bacteria that generate electrical current when consuming organic matter in the wastewater; the current, in turn, aids the water splitting process.

The team, led by Zhiyong Jason Ren, professor of civil and environmental engineering and the Andlinger Center for Energy and the Environment, chose wastewater from breweries for the test. They ran the wastewater through the chamber, used a lamp to simulate sunlight, and watched the organic compounds breakdown and the hydrogen bubble up.

Read more at Princeton University - Engineering School

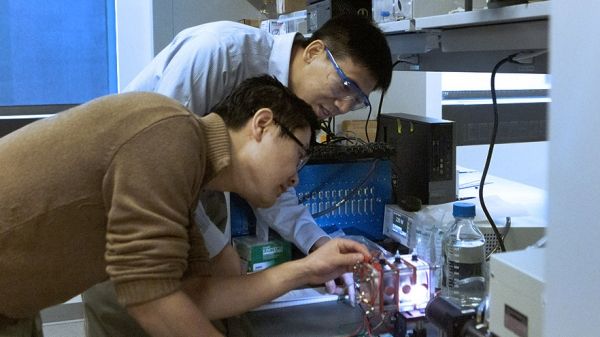

Image: Professor Zhiyong Jason Ren and Lu Lu, associate research scholar at the Andlinger Center for Energy and the Environment. Credit: Princeton University