Hearing aids, dental crowns, and limb prosthetics are some of the medical devices that can now be digitally designed and customized for individual patients, thanks to 3-D printing. However, these devices are typically designed to replace or support bones and other rigid parts of the body, and are often printed from solid, relatively inflexible material.

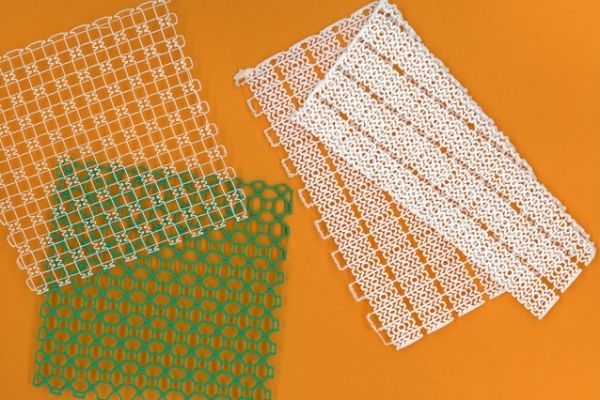

Now MIT engineers have designed pliable, 3-D-printed mesh materials whose flexibility and toughness they can tune to emulate and support softer tissues such as muscles and tendons. They can tailor the intricate structures in each mesh, and they envision the tough yet stretchy fabric-like material being used as personalized, wearable supports, including ankle or knee braces, and even implantable devices, such as hernia meshes, that better match to a person’s body.

As a demonstration, the team printed a flexible mesh for use in an ankle brace. They tailored the mesh’s structure to prevent the ankle from turning inward — a common cause of injury — while allowing the joint to move freely in other directions. The researchers also fabricated a knee brace design that could conform to the knee even as it bends. And, they produced a glove with a 3-D-printed mesh sewn into its top surface, which conforms to a wearer’s knuckles, providing resistance against involuntary clenching that can occur following a stroke.

Read more at Massachusetts Institute of Technology

Image: MIT engineers 3-D-print stretchy mesh, with customized patterns designed to be flexible yet strong, for use in ankle and knee braces. CREDIT: Felice Frankel