The production of hydrogen peroxide can be much safer and simpler through a process developed at Rice University.

A reactor developed by Haotian Wang and his colleagues at Rice’s Brown School of Engineering requires only air, water and electricity to make the valuable chemical in the desired concentration and high purity.

Their electrosynthesis process, detailed in Science, uses an oxidized carbon nanoparticle-based catalyst and could enable point-of-use production of pure hydrogen peroxide solutions, eliminating the need to transport the concentrated chemical, which is hazardous.

By using a solid electrolyte instead of traditional liquid electrolyte, it also eliminates the need for product separation or purification used in current processes, so no contaminating ions will be involved.

“If we have electricity from a solar panel, we can literally get hydrogen peroxide from just sunlight, air and water,” said Wang. “We don’t need to involve organics or fossil fuel consumption. Hydrogen peroxide synthesis by traditional, huge chemical engineering plants generates organic wastes, consumes fossil fuels and emits carbon dioxide. What we’re doing is green synthesis.”

Read more at Rice University

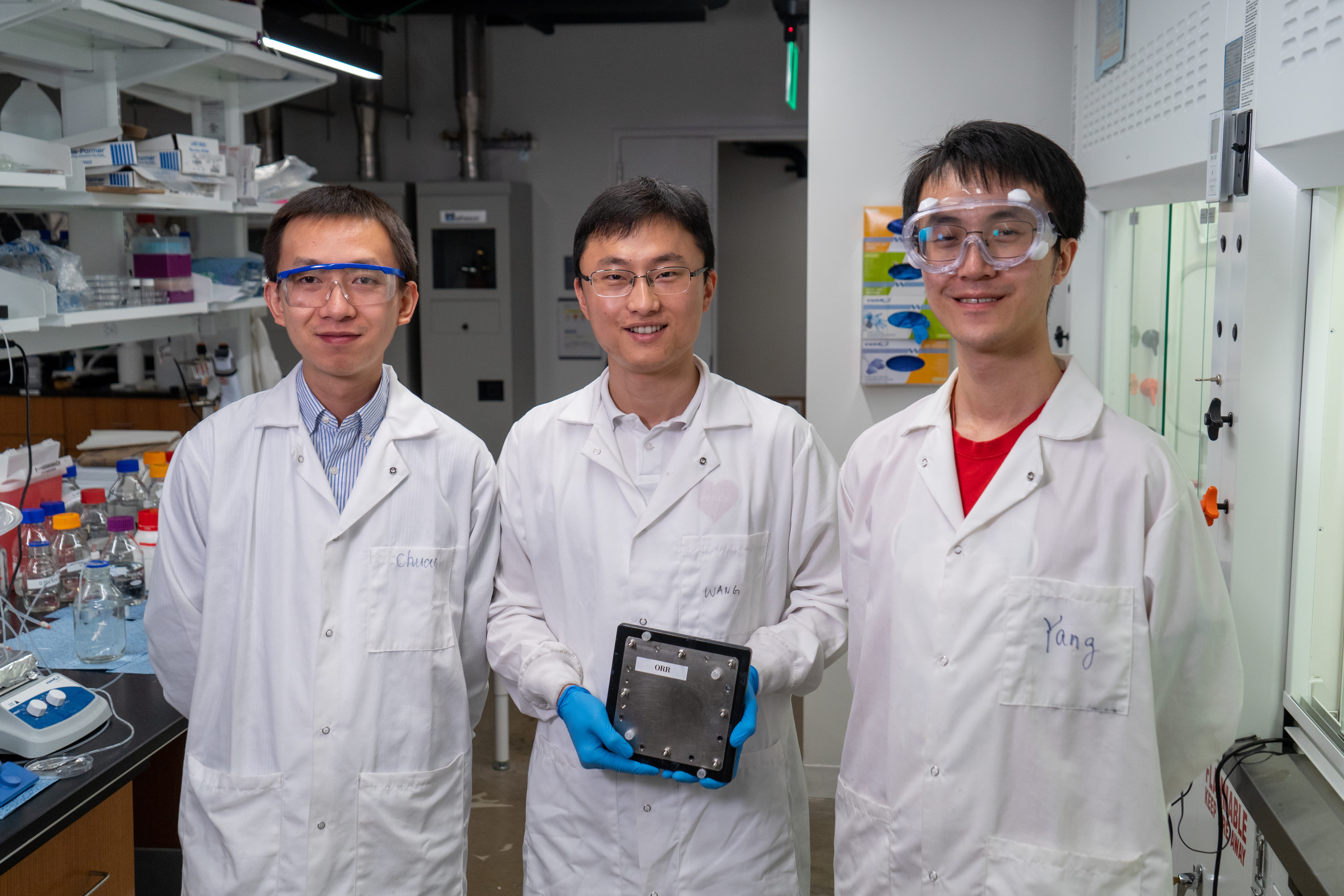

Photo: Rice University researchers – from left, Chuan Xia, Haotian Wang and Yang Xia – show a scaled-up hydrogen peroxide reactor. Photo by Brandon Martin