Cornell researchers have made a new discovery about how seemingly minor aspects of the internal structure of bone can be strengthened to withstand repeated wear and tear, a finding that could help treat patients suffering from osteoporosis. It could also lead to the creation of more durable, lightweight materials for the aerospace industry.

The team’s paper, “Bone-Inspired Microarchitectures Achieve Enhanced Fatigue Life,” was published Nov. 18 in the Proceedings of the National Academy of Sciences.

For decades, scientists studying osteoporosis have used X-ray imaging to analyze the structure of bones and pinpoint strong and weak spots. Density is the main factor that is usually linked to bone strength, and in assessing that strength, most researchers look at how much load a bone can handle all at once.

But a team led by senior author Christopher J. Hernandez, associate professor in the Sibley School of Mechanical and Aerospace Engineering and in the Meinig School of Biomedical Engineering, is interested in long-term fatigue life, or how many cycles of loading a bone can bear before it breaks.

Read more at Cornell University

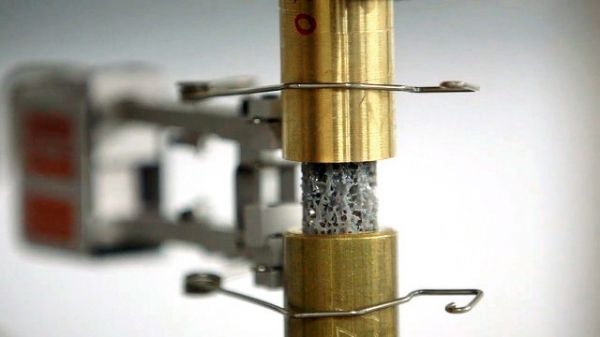

Image: Cornell researchers led by Christopher J. Hernandez used a 3D printer to manufacture bone-inspired material made from a urethane methacrylate polymer and then tested its durability. The researchers were able to increase the material’s fatigue life by up to 100 times by strengthening internal rod-like struts. CREDIT: Cornell University