Researchers from UCLA Samueli School of Engineering, Rice University and UC Santa Barbara have developed an easier and greener way to create syngas.

A study detailing their work is published today in Nature Energy.

Syngas (the term is short for “synthesis gas”) is a mixture of carbon monoxide and hydrogen gases. It is used to make ammonia, methanol, other industrial chemicals and fuels. The most common process for creating syngas is coal gasification, which uses steam and oxygen (from air) at high temperatures, a process that produces large amounts of carbon dioxide.

One more environmentally friendly way to create syngas, called methane dry reforming, involves getting two potent greenhouse gases to react — methane (for example, from natural gas) and carbon dioxide. But that process is not widely used at industrial scales, partly because it requires temperatures of at least 1,300 degrees Fahrenheit (700 degrees Celsius) to initiate the chemical reaction.

Over the past decade, researchers have tried to improve the process for creating syngas using various metal alloys that could catalyze the required chemical reaction at lower temperatures. But the tests were either inefficient or resulted in the metal catalysts being covered in coke, a residue of mostly carbon that builds up during the process.

Read more at University of California - Los Angeles

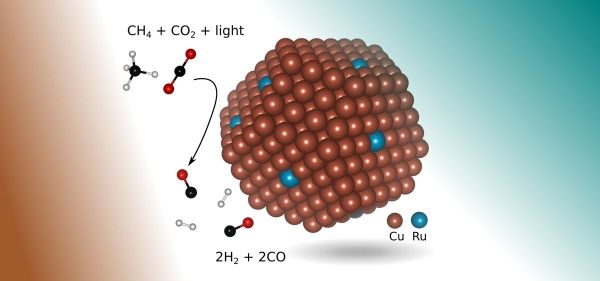

Image: Schematic showing the atomic structure of the copper-ruthenium nanoparticle catalyst. When exposed to visible light at room temperature, the catalyst converts methane (CH4) and carbon dioxide (CO2) into syngas: carbon monoxide (CO) and hydrogen gas (H2). CREDIT: John Mark Martirez/UCLA