For decades, researchers have considered the potential for cooling hot electronic devices by blowing on them with high-speed air jets. However, air jet cooling systems are not widely used today. Two of the biggest obstacles that prevent the use of these systems is their complexity and weight. Air jet systems must be made of metal to be able to handle the pressure associated with air jets whose speed can exceed 200 miles per hour. And the air handling system can be complex with many discrete components that manage the air flow and direct the air onto the hot spots where cooling is required.

Now, researchers at the University of Illinois at Urbana-Champaign have demonstrated a new type of air jet cooler that overcomes previous barriers to jet cooling systems. Using additive manufacturing, the researchers created an air jet cooling system in a single component that can direct high-speed air onto multiple electronics hot spots. The researchers manufactured the cooling system from strong polymer materials that can withstand the harsh conditions associated with high-speed air jets.

“The design freedom of additive manufacturing allows us to create cooling solutions that have sizes and shapes not previously possible,” said William King, Andersen Chair and Professor of Mechanical Science and Engineering. “This really opens up a new world of opportunities for thermal management.”

Read more at University of Illinois at Urbana-Champaign

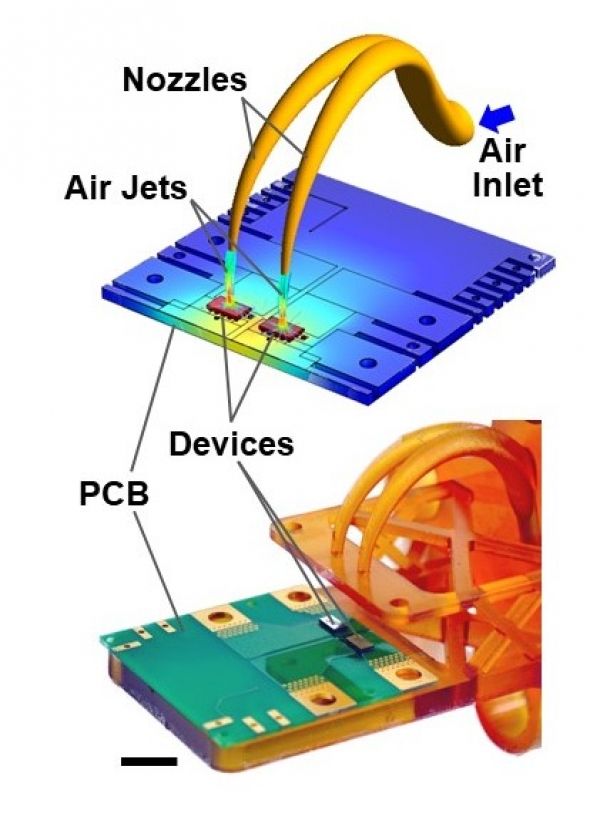

Image: Schematic (top) and a photograph (bottom) of additively manufactured nozzles showing how the impinging jet cools working GaN devices on a PCB. The scale bar represents 10 mm. CREDIT: University of Illinois at Urbana-Champaign