Solar energy that reaches the Earth is about 125 million gigawatt (Gw). When this solar energy generated for a year is converted into oil, it is 100 trillion ton which is ten thousand times more than the amount of oil energy the world uses in a year. So, it is no surprising when one of the coffee commercial ads said, “The sunlight reaching the Earth for 30 seconds is enough for the entire world to use energy for 48 hours.” Converting this solar energy into electrical energy is solar cell energy. Recently a research team from POSTECH developed an eco-friendly organic electronic material technology to solve an environmental issue which can occur during the production process of the conventional perovskite solar cells.

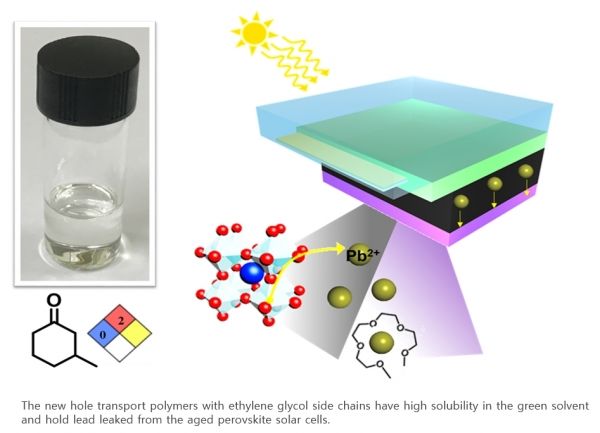

POSTECH research team consisted of Prof. Taiho Park and Junwoo Lee, a student in joint MS-PhD program developed Alkoxy-PTEG, hole transport polymers that could be dissolved in peppermint oil, by applying ethylene glycol side chains when they produced high efficiency perovskite solar cells. Also, they confirmed that this polymer captured leaking lead in the aged perovskite solar cells.

The essential material of a solar cell is photoactive layer which absorbs solar energy. Perovskite uses materials with crystal structures as photoactive layers and its distinctive feature is absorbing lights very well which is possible by using cheap inorganic and organic materials. For this reason, it is referred to as ‘next-generation solar cell.’ But the problem is that organic materials of transport layer used in a solar cell uses toxic chemical solvent in the production process and can harm environment and humans and therefore cannot be mass produced. In addition, when lead in the perovskite becomes aged, it can leak.

Read more at Pohang University of Science and Technology

Image Credit: Pohang University of Science and Technology