The brain is one of our most vulnerable organs, as soft as the softest tofu. Brain implants, on the other hand, are typically made from metal and other rigid materials that over time can cause inflammation and the buildup of scar tissue.

MIT engineers are working on developing soft, flexible neural implants that can gently conform to the brain’s contours and monitor activity over longer periods, without aggravating surrounding tissue. Such flexible electronics could be softer alternatives to existing metal-based electrodes designed to monitor brain activity, and may also be useful in brain implants that stimulate neural regions to ease symptoms of epilepsy, Parkinson’s disease, and severe depression.

Led by Xuanhe Zhao, a professor of mechanical engineering and of civil and environmental engineering, the research team has now developed a way to 3D print neural probes and other electronic devices that are as soft and flexible as rubber.

The devices are made from a type of polymer, or soft plastic, that is electrically conductive. The team transformed this normally liquid-like conducting polymer solution into a substance more like viscous toothpaste — which they could then feed through a conventional 3D printer to make stable, electrically conductive patterns.

Read more at Massachusetts Institute of Technology

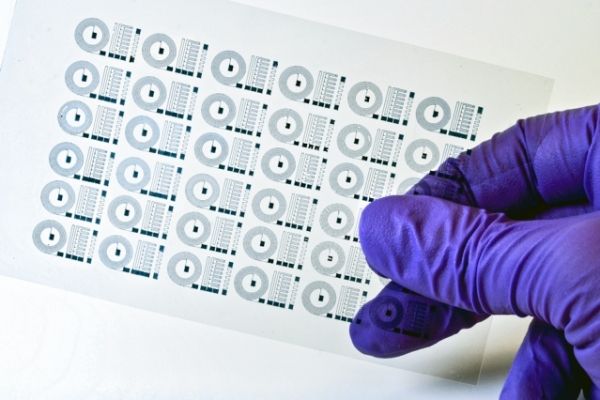

Image: MIT researchers have 3-D-printed soft electronically active polymers into a number of devices, including a pliable neural electrode, and (shown here) a flexible circuit. Image: courtesy of the researchers