Northwestern Engineering synthetic biologists have developed a new rapid-prototyping system to accelerate the design of biological systems, reducing the time to produce sustainable biomanufacturing products from months to weeks.

As global challenges like climate change, population growth, and energy security intensify, the need for low-cost biofuels and bioproducts — like medicines and materials — produced using sustainable resources increases. Industrial biotechnology, which uses microbial cellular factories to harness enzyme sets that can convert molecules to desirable chemical product, has shown potential to address these needs. However, designing, building, and optimizing these pathways in cells remains complex and slow, unable to keep up with the dynamic shifts in needs.

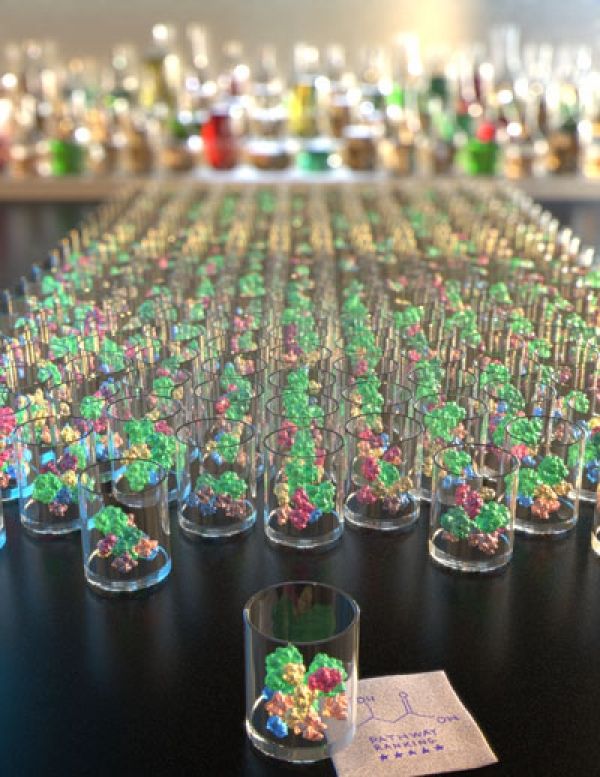

The new platform, called in vitro Prototyping and Rapid Optimization of Biosynthetic Enzymes (iPROBE), provides a quick and powerful design-build-test framework to discover optimal biosynthetic pathways for cellular metabolic engineering that could impact a range of industries (or issues) from clean energy to consumer products.

Read more at Northwestern University

Image: iPROBE employs a mix-and-match analysis of different enzyme combinations to discover optimal biosynthetic pathways sustainable biomanufacturing. CREDIT: Northwestern University