Using the Canadian Light Source synchrotron, a University of Saskatchewan-led research team has developed a method for monitoring uranium contaminants in mine tailings using samples from McClean Lake, SK.

While mining companies work to extract as much uranium as possible from processed ore, small amounts remain in the solid and liquid residue—called tailings—left over from the milling process.

To protect the downstream environment from potential impacts of the solid waste, the Canadian Nuclear Safety Commission requires companies to monitor the chemistry of uranium and other potentially harmful elements in their tailings facilities.

Numerous researchers have studied the chemistry of nickel, arsenic, selenium and molybdenum in Orano Canada’s tailings management facility at McClean Lake, but to date little was known about residual uranium. One of the challenges has been the extremely low concentrations of the element left after processing at Orano’s ore mill, which began operating in 1997.

Continue reading at University of Saskatchewan.

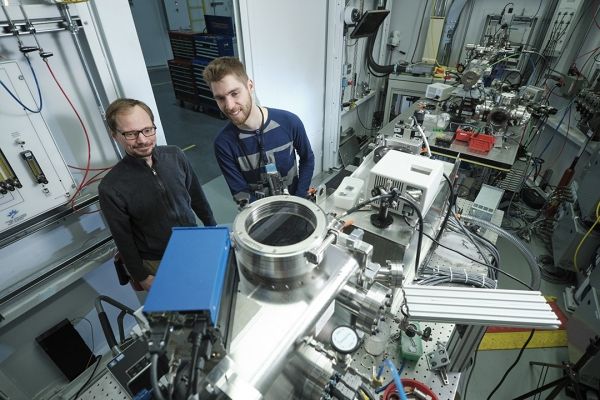

Image via David Stobbe.