Materials used in biomedicine must be characterized by controlled biodegradability, sufficient strength and total absence of toxicity to the human body. The search for such materials is, therefore, not a simple task. In this context, scientists have been interested in magnesium for a long time. Recently, using such techniques as positron annihilation spectroscopy, the researchers were able to demonstrate that magnesium subjected to surface mechanical attrition treatment obtains the properties necessary for a biocompatible material.

Materials showing controlled corrosion rate are gaining more and more interest. This applies in particular to biomedicine, where implants made of natural or synthetic polymers are used. Their advantage is that the rate of decomposition can be easily adjusted under physiological conditions. On the other hand, the mechanical properties of these materials are deteriorated in the environment of the human body, making them unsuitable for high-stress applications. For this reason, metallic implants based on magnesium that is entirely harmless to the human body seem to be a good option.

Magnesium is the lightest metal that can be used in structural applications. Due to its mechanical, thermal and electrical properties as well as biodegradability and the controlled rate of corrosion, it sparks great interest in researchers dealing with biocompatible implants. Despite these advantages, the use of magnesium as a biomaterial for the production of implants has not been easy due to the relatively high corrosion rate in the human body environment. However, this problem can be overcome by using appropriate coatings.

Read more at Institute of Nuclear Physics

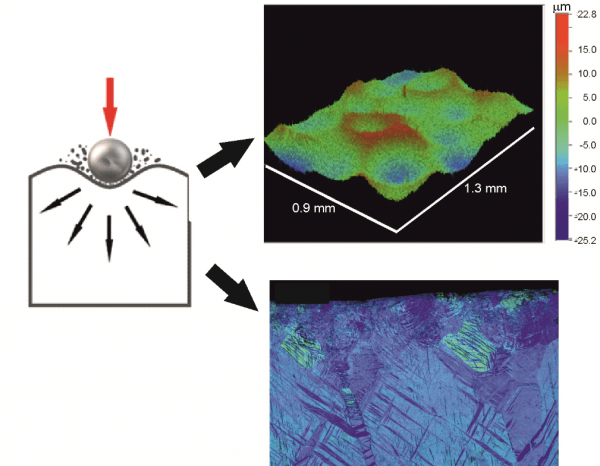

Image: Surface mechanical attrition treatment (SMAT) of magnesium improves its strength and corrosion resistance. (Source: IFJ PAN)