UD researchers report low-pressure method to convert industrially processed biomass into plastics, chemicals.

It’s no secret that we need more sustainable materials if we hope to help the planet. Bio-derived materials are one potential option, but they must be economical if anyone is going to use them.

For instance, a better bio-based milk jug would be great. However, if the milk sells for $20 per gallon because the cost of the jug increases from $1 to $17, no one will buy it.

Led by Professor Thomas H. Epps, III, a team of University of Delaware researchers and collaborators from CanmetENERGY are keeping just this type of economics in mind as they look for ways to upcycle biomass into new products. Take lignin, for example. Lignin is a component of plants and trees that provides strength and stiffness to help the flora stand up to what Mother Nature throws its way.

In the pulp and paper industry, however, lignin is a waste left over from making paper products. This type of lignin, known as technical lignin, is considered the dirtiest of the dirty, something that isn’t usable — except maybe to burn for heat or to add to tires as filler.

Read more at University of Delaware

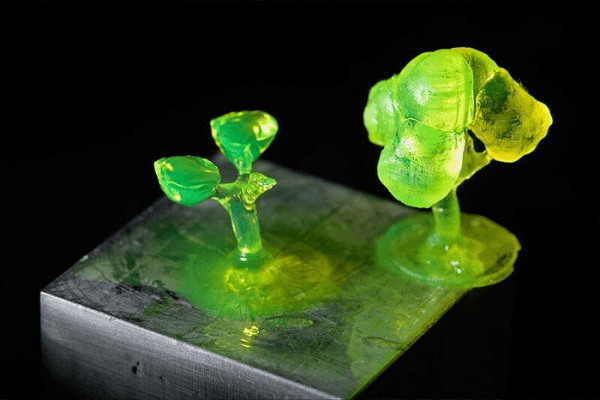

Image: One of the end-products the UD researchers and colleagues are investigating is the creation of bio-resins for 3D printing. (Credit: Photo courtesy of Paul Pranda)