20 people die every day waiting for an organ transplant in the United States, and while more than 30,000 transplants are now performed annually, there are over 113,000 patients currently on organ waitlists. Artificially grown human organs are seen by many as the “holy grail” for resolving this organ shortage, and advances in 3D printing have led to a boom in using that technique to build living tissue constructs in the shape of human organs. However, all 3D-printed human tissues to date lack the cellular density and organ-level functions required for them to be used in organ repair and replacement.

Now, a new technique called SWIFT (sacrificial writing into functional tissue) created by researchers from Harvard’s Wyss Institute for Biologically Inspired Engineering and John A. Paulson School of Engineering and Applied Sciences (SEAS), overcomes that major hurdle by 3D printing vascular channels into living matrices composed of stem-cell-derived organ building blocks (OBBs), yielding viable, organ-specific tissues with high cell density and function. The research is reported in Science Advances.

“This is an entirely new paradigm for tissue fabrication,” said co-first author Mark Skylar-Scott, Ph.D., a Research Associate at the Wyss Institute. “Rather than trying to 3D-print an entire organ’s worth of cells, SWIFT focuses on only printing the vessels necessary to support a living tissue construct that contains large quantities of OBBs, which may ultimately be used therapeutically to repair and replace human organs with lab-grown versions containing patients’ own cells.”

Read more at: Wyss Institute for Biologically Inspired Engineering at Harvard

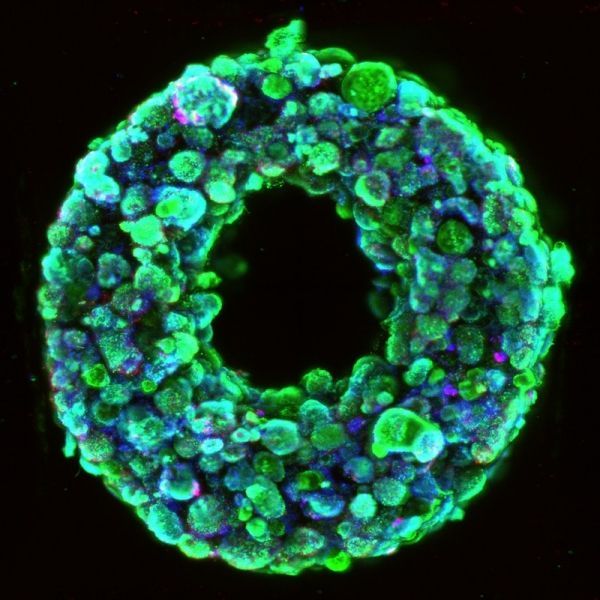

Living embryoid bodies surround a hollow vascular channel printed using the SWIFT method. (Photo Credit: Wyss Institute at Harvard University)